VENTLIT complexes

Industrial series of VENTLIT complexes is designed for removal of odourous substances from ventilation emissions at municipal and industrial enterprises.

- Unit capacity from 2 to 12 thousand m³/h

- Deep removal of odours : hydrogen sulphide, mercaptans, VOCs, ammonia.

- Effective work at temperature from -45 to +40 °С

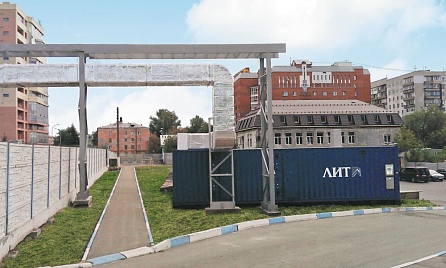

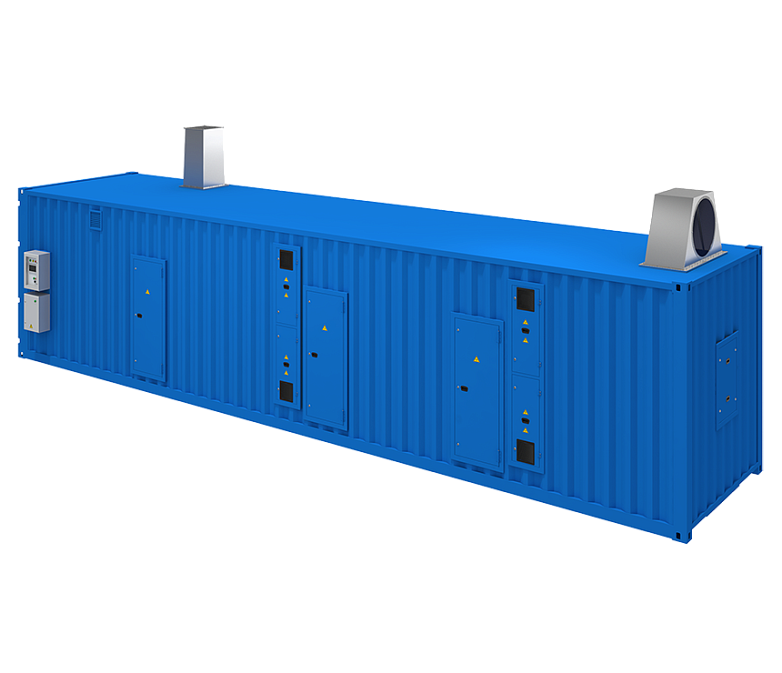

- Convenient container execution

Combination of two wavelengths of UV radiation (185 and 254 nm) with the formation of active oxidation centres (OH-radicals) effectively destroys odours molecules.

The effectiveness of VENTLIT complexes is stable to peak concentrations of odours (both maximum and minimum), does not depend on the temperature regime, increases with increasing air humidity.

Depending on the composition and concentrations of odours in the air to be purified, different purification schemes are used.

VENTLIT complexes are produced in the form factor of sea containers of different sizes, which makes it convenient to transport the equipment and install it at the site. There is no need to build capital structures.

The basis of technology of odours removal in VENTLIT complexes is photo-sorption-catalytic method, providing deep degree of purification in the presence of a wide range of odours (hydrogen sulphide, mercaptans, ammonia, volatile organic compounds, etc.) in the purified air. High air humidity, typical for objects of housing and communal services, only increases the efficiency of purification.

VENTLIT complexes are equipped with a system of automatic control and capacity control depending on the concentration of odours and the flow rate of purified air. All internal elements and reactor walls are made of special stainless steels, teflon and other corrosion-resistant materials.

Depending on the quality of supplied air, VENTLIT complexes can be equipped with air pre-treatment and purification systems.

It is recommended to carry out a technological survey of the object of application before selecting the equipment, as the efficiency of the complex application is influenced by a wide range of characteristics of the purified air and conditions of its location and operation

Purified air is treated with ultraviolet radiation with wavelengths 185 and 254 nm, which leads to the formation of active oxidation centres, primarily O, OH ̇, O3 and others. The processes of odours transformation are carried out first in the bulk part of the photoreactor, then air is supplied to the sorption-catalytic stage, where the underoxidised components are adsorbed and pre-oxidised in slower processes by active particles from the gas phase. Such a combination of methods and processes allows to provide a deep degree of purification in the presence of a wide range of odours (hydrogen sulphide, mercaptans, ammonia, volatile organic compounds, etc.).